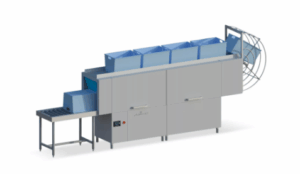

In the ever-changing environment of crate washing technology, Rhima’s RC 401-crate-washer stands out as an innovative solution that sets new standards for efficiency as well as creativity. Previously known as the VX 401 model, this innovative crate washing machine sets new industry norms with an incredible capacity of around 400-450 crates per hour.

Tailored to satisfy the needs of large farms, enterprises, as well as organisations in need of quicker crate cleaning procedures, the RC 401 is a genuine game changer, demonstrating a dedication to excellence in crate cleanliness as well as technological integration.

Automate Your Washing System With RC 401 Crate Washer

RC 401 crate washer by Rhima Australia will simply revolutionise your washing method. This machine offers a variety of choices and easily combines robots for activities such as loading, unloading, stacking, and destacking at both ends. This novel technique considerably minimises the need for physical work, hence improving the efficiency of your washing operation.

By automating key operations, the RC 401 Crate Washer allows you to concentrate on both productivity as well as quality. It guarantees that your washing system runs at top efficiency, resulting in unmatched crate hygiene.

Washing Stages: Pre Wash, Wash, Rinse

Hot Chemical Wash

The RC 401 crate washer by Rhima Australia starts with a hot (65°C) chemical wash, ensuring the crates are thoroughly cleaned. This procedure is critical to keeping sanitary standards, particularly in businesses where cleanliness is vital.

Fresh Water Final Rinse

Following the chemical wash, the RC 401 uses a fresh water final rinse with a minimum temperature of 82°C. This procedure is consistent with HACCP requirements, giving an additional degree of assurance about the sanitation of the cleaned crates. Notably, water usage is reduced, and the machine has a water recycling system, contributing to environmental initiatives.

Energy and Water Consumption Efficiency

Heat Recovery Units

Rhima’s devotion to energy efficiency is seen in the available heat recovery units. These devices provide the machine with cold water while also conserving electricity. The system preheats the incoming water by collecting steam generated during machine operation and passing it via a heat exchanger, lowering total energy usage.

Detergent Dispenser

The RC 401 may be equipped with a detergent dispenser for further convenience and accuracy. This function allows for automated dosing as well as the injection of chemicals into the wash cycle, resulting in excellent cleaning and hygiene.

Blowers for Drying

Blowers can be installed on the RC 401 to ensure that the washing operation runs smoothly. These blowers help to dry the cleaned crates effectively, reducing the time necessary for future handling.

Additional Features for Optimal Performance

Insulated Doors

The RC 401 crate washer’s insulated doors help to maintain a consistent temperature inside the washing chamber. This not only provides proper cleaning but also reduces the power consumption of the boiler’s heating components.

CPF – Customised Water Pressure

The Customised Pressure Function (CPF) is a user-friendly function that lets you easily alter the water pressure throughout the pre wash or wash cycle. This customisation meets the individual demands of consumers by giving flexibility in the washing process.

Stainless Steel Construction

The Rihma’s RC 401 crate washer is made of AIS 304 and 316 stainless steel, which protects it against strong cleaning chemicals as well as saltwater. This robust design assures the machine’s lifespan, even in harsh industrial conditions.

Closing Thoughts On RC 401 Crate Washer

Rhima’s RC 401 crate washer exemplifies innovative and efficient crate-cleaning technology. Its automated loading mechanism, energy-efficient features, and sanitary design are all intended to improve performance while reducing environmental effects. Embrace the future of crate cleaning with Rhima’s groundbreaking RC 401-crate washer, where technology meets cleanliness for unparalleled results.